Surface Innovation at Nanoscale

Our patent-pending process transforms metallic surfaces into functional materials – starting with antibacterial performance, and unlocking new possibilities across industries.

The nanoshape Technology

At nanoshape, we engineer surface functionalities by modifying the material itself.

Our patent-pending process is based on a cutting-edge hydrothermal oxidation method. This process allows the creation of highly controlled nanostructures on metals like titanium or aluminum and various others - directly on the original surface.

Inspired by nature, these structures are known to reduce bacterial adhesion and biofilm formation.

Depending on the design, nanostructures can also influence the wetting behaviour, the resulting friction, the light interaction or even the contamination behavior.

no coatings,

no additives

Pure surface modification - long-term stability, no degradation over time.

compatible with complex geometries

Suitable for curved, porous, or even micro-structured parts.

mechanically

robust

Surfaces withstand real-world mechanical and chemical stress.

scalable and

industry-ready

Designed for series production as a batch process as one of the last steps in production.

Surface Functionalization

Surface functionalization is a key strategy in modern materials science.

By modifying only the outermost layer of a material, surfaces can be tailored for specific interactions – from reducing friction to repelling water, from improving adhesion to reducing bacterial growth.

Various methods exist to achieve such effects, including coatings, plasma treatments, etching, and laser structuring. While effective, many of these techniques come with limitations: they may involve complex chemistries, lack long-term stability, or be difficult to apply to complex geometries or are just too expensive for mass application.

Inspired by Nature

Nature has evolved countless functional surfaces to survive and adapt – often at the micro- and nanoscale. Examples include:

Lotus leaves, which repel water through hierarchical surface structures

Gecko feet, which adhere through microscopic hair-like structures

Cicada and dragonfly wings, which show antibacterial properties thanks to nanoscale pillars that damage bacterial membranes

These biological models demonstrate what’s possible – and serve as inspiration for our own surface designs. With nanoshape, we translate these principles into a scalable, industrial technologies.

Key properties

At nanoshape, we engineer surface functionalities by modifying the material itself.

Our patent-pending process is based on a cutting-edge hydrothermal oxidation method. This process allows the creation of highly controlled nanostructures on metals like titanium or aluminum and various others - directly on the original surface.

Inspired by nature, these structures are known to reduce bacterial adhesion and biofilm formation.

Depending on the design, nanostructures can also influence the wetting behaviour, the resulting friction, the light interaction or even the contamination behavior.

Bacteria repelling function

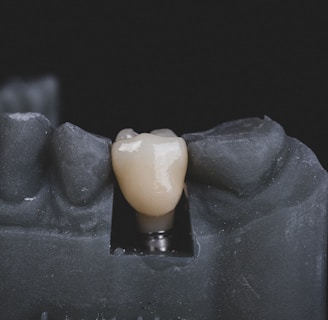

For soft-tissue and hard tissue applications

At nanoshape, we engineer surface functionalities by modifying the material itself.

Our patent-pending process is based on a cutting-edge hydrothermal oxidation method. This process allows the creation of highly controlled nanostructures on metals like titanium or aluminum and various others - directly on the original surface.

Inspired by nature, these structures are known to reduce bacterial adhesion and biofilm formation.

Depending on the design, nanostructures can also influence the wetting behaviour, the resulting friction, the light interaction or even the contamination behavior.

Superhydrophyllic wetting behaviour

At nanoshape, we engineer surface functionalities by modifying the material itself.

Our patent-pending process is based on a cutting-edge hydrothermal oxidation method. This process allows the creation of highly controlled nanostructures on metals like titanium or aluminum and various others - directly on the original surface.

Inspired by nature, these structures are known to reduce bacterial adhesion and biofilm formation.

Depending on the design, nanostructures can also influence the wetting behaviour, the resulting friction, the light interaction or even the contamination behavior.

At nanoshape, we engineer surface functionalities by modifying the material itself.

Our patent-pending process is based on a cutting-edge hydrothermal oxidation method. This process allows the creation of highly controlled nanostructures on metals like titanium or aluminum and various others - directly on the original surface.

Inspired by nature, these structures are known to reduce bacterial adhesion and biofilm formation.

Depending on the design, nanostructures can also influence the wetting behaviour, the resulting friction, the light interaction or even the contamination behavior.

Explore the applications

Our technology is not a one-size-fits-all solution.

Each application requires specific properties to fit its individual challenges. We can fine-tune our technology to meet your needs. Whether you're developing medical implants, or surgical devices, filtration components or air filtration systems or high-end technical parts for aerospace applications, we work with you to achieve the right surface functionality.

You have a specific

Problem?

Then we might have the right solution for you!

We offer you fast and cost-effective feasibility analysis to test the suitability of our technology and solutions for your material or individual components. This will help you find a customized solution to solve your individual problems.

Based on the results, transfer projects for pre-series development and series integration can be carried out. Please do not hesitate to contact us. We will be happy to advise you.